Diesel Exhaust Fluid (DEF) is a fairly simple and non-hazardous solution that is making a large impact on reducing air pollution. It is comprised of 32.5 percent urea and 67.5 percent de-ionized water that, when sprayed into the exhaust stream of diesel engines, turns mono-nitrogen oxides (NOx) emissions into harmless nitrogen and water.

But just because DEF is not hazardous isn’t the end of the story when it comes to storage and handling. DEF is corrosive for some metals, including carbon steel, aluminum, copper and zinc. So it should not be stored or dispensed with anything that contains these materials. ISO.org offers some details about these materials at http://www.iso.org/iso/catalogue_detail.htm?csnumber=40793.

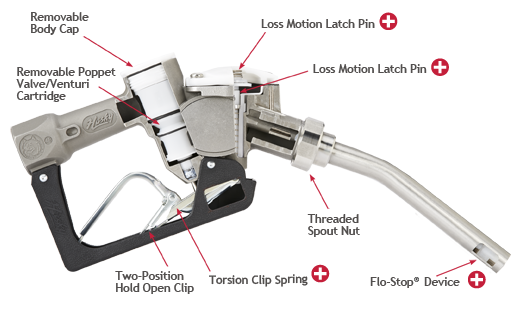

The components used in DEF nozzles are more expensive than those used in conventional fueling systems. Husky offers a stainless steel nozzle with materials that are 100 percent compatible with DEF, a light-weight Polymer DEF nozzle with an Acetal body that complies with ISO Standard 22241-2:2006, and a new version of its popular X family of nozzles that contains the essential components for handling DEF. The variety of available DEF nozzles provides options to meet any dispensing situation.

DEF can cause dispensing equipment to clog since the urea-based fluid will crystalize outside its optimum temperature range of 12-86 F. Husky engineers solved the problem by designing the only DEF nozzle in the industry, the company’s stainless steel model, with removable cartridge assemblies for critical components that come in contact with DEF. Simply changing the affected modular part keeps the DEF flowing when dipping a clogged nozzle in de-ionized water doesn’t solve the problem.

Sign up to stay up-to-date with the latest news and offers from Husky.